Applications

CALMS – Characterization of Additive Laser Manufactured Structures

Laser additive manufacturing (LAM) of aluminium alloys is already used for various industrial applications. The dominating LAM technology in this field is the powder-based selective laser melting (SLM). However, the range of aluminium alloys available as qualified powder for SLM is very limited and powder handling is in general also laborious. For laser metal deposition (LMD) with wire conventional retrofitted laser welding facilities can be used and the handling of the feedstock material is facilitated. Moreover, a larger range of aluminium alloys is commercially available for this LAM technology in form of filler wires typically used for fusion welding. By using wire instead of powder as feedstock material considerable higher deposition and utilisation rates are possible. Thus, large-scale surface-coatings as well as structures can be realised. By coupling the knowledge about the process, the (new) materials and the microstructure it is possible to tailor the resulting properties of structures.

ILMS – Integrity of Laser Processed Materials and Structures

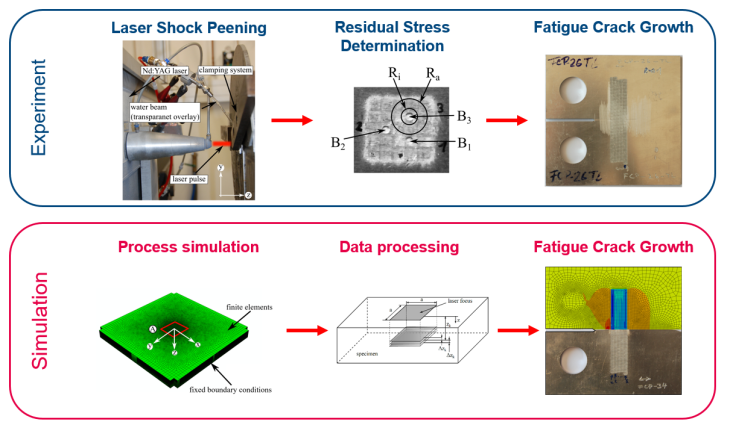

Laser shock peening (LSP) can be used to improve the fatigue performance of lightweight structures and therefore provides a method to treat one of the main failure causes in the aircraft industry. The idea is to introduce compressive residual stresses in critical regions of fatigue to reduce crack driving tensile stresses and to retard the fatigue crack growth or even the fatigue crack initiation. Pressure pulses, induced by short high-energy laser pulses, cause local plastic deformations next to the surface of the material. The elastic relaxation of the plastically deformed area results in the residual stress field. By performing LSP with a Nd:YAG laser, which enables laser pulses with an energy of 5 J and a duration of 10 – 20 ns with a squared laser focus, a higher maximum and penetration depth of compressive residual stresses is achievable compared to traditional methods, e.g. shot peening. Residual stresses can be measured by the incremental hole drilling method based on the integral method.

Numerical simulations are used to gain a deeper insight of the high-speed process and its physical phenomena (e.g. shock wave propagation, plastically affected area, etc.). In a close interaction, numerical and experimental work drive the investigation of the relation between LSP-parameters and resulting residual stresses, answering the question how residual stresses after LSP can be predicted efficiently. Furthermore, it is necessary to study the effect of residual stresses on the fatigue behavior to find the residual stress field, which is needed to manipulate the fatigue crack growth in a certain way. In this way, for example, optimal shot patterns for the process can be identified. As final result a simulation strategy is develop including the prediction of LSP-generated residual stresses, the stress transfer to the fatigue propagation model and the prediction of the fatigue crack propagation rate as final result.