Current Projects

The department Powder-based Materials Development participates in various internal and external projects, including national and European funding programmes as well as bilateral projects with industrial partners. Examples for current financially funded projects are listed in the following.

I²B MgELB - Electronic Laboratory Notebook

Developing an Electronic Lab Notebook for the interdisciplinary field of Metallic Biomaterials

To facilitate the digitalization efforts at the Institute of Metallic Biomaterials, we are developing Herbie, a combined electronic laboratory notebook and research database. We are faced with these main challenges:

- Herbie has to cover a wide range of different scientific fields (material science, biology, medicine, ...)

- Data among these fields must be connected

- We need rigid data structures to achieve FAIR standards, but also

- flexibility to support a scientific workflow

Key-features of Herbie are:

- Interconnection of multiple disciplines (material science, biology, medicine)

- Easy and flexible documentation, including images, videos, files upload

- Very structured, well-adapted protocols for standardized processes

- Data-points and specimens can be referenced within the journal

- Herbie helps creating a rich and connected data pool

The Herbie code including documentation will soon be published open source and the link to the GitHub repository will be provided here.

Until then, feel free to contact us if you would like to know more about Herbie or to evaluate it as a solution for your research.

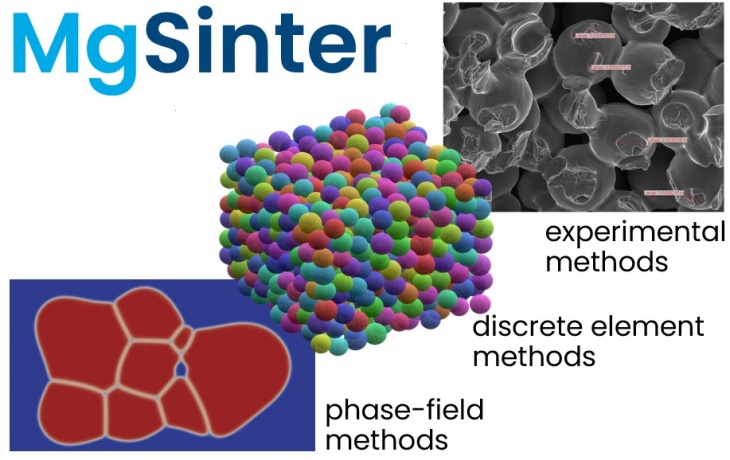

I²B MgSinter - Sinter modelling

Multiphysics simulation of the sintering process of biodegradable magnesium implants

Key questions for the application of magnesium alloys for biodegradable implants are how to control the degradation rate and how to guarantee best mechanical properties. Sintering of metallic powders as applied in our department offers very flexible opportunities to tune both properties. However, it is necessary to understand precisely how the sinter process affects microstructure and properties. Whenever new Mg-based materials are sintered, the processing parameters have to be adjusted. This requires time-consuming and costly experiments. Replacing these experiments by cheaper and faster computer simulations is a key objective of the project. To achieve this goal, we are developing an efficient multiscale numerical framework where several modelling approaches are combined in order to obtain maximum flexibility, accuracy and performance.

The main features of the developed framework are:

- Flexibility in terms of choice of geometries of both specimens and individual particles

- Efficient model calibration strategy that employs a lightweight elementary 2-particles approach for extraction of the diffusion properties of a given material from experimental data

- High efficiency thanks to combination of different models used at different stages of sintering: the discrete element method is applied for the early stage and the phase-field technique implemented with the finite element method - is for the later ones

- Theoretical rigor of the phase-field model that couples mechanics and thermodynamics on the ground of continuum physics

- Accurate capturing of neck growth, shrinkage and grain coarsening

- Experimental validation of the numerical simulations

- High computational performance thanks to the use of C++, deal.ii library and MPI parallelization

For more details on the being developed numerical tools, feel free to contact us. This work is performed in close cooperation with the Hereon Institute for Material Systems Modeling.