Sustainable Materials

Modern applications for medicine and sustainable products for daily needs place high demands on the multifunctionality of materials. Our “Polymer Chemistry” department researches the integration of a wide range of functions, such as degradability, biointeractivity and stimulus sensitivity. Our work encompasses the molecular level as well as the upscaling of functional polymers for medical products and autonomous electronic systems. The fields of activity regarding synthetic compounds aims at smart or sustainable (medical) products as well as living spaces. Materials research thus spans the spectrum from synthesizing monomers and the oligomeric precursor to polymer libraries and inks for 3D printing. The compounds are comprehensively characterized chemically and, with promising candidate materials, the technical scale-up of the synthesis is conducted.

The Active Polymers department develops innovative multifunctional plastics (polymers) for medical applications. The research task is the design and synthesis of the new materials for which the synthesis elements, i.e. the required monomers and pre-polymers, are also designed by the staff. The focus is on the use of synthetic starting materials.

Particular attention is paid to the development of stimuli-sensitive polymer systems, i.e. materials that react to external stimuli. The focus here is on the investigation of new materials that move reversibly and on the implementation of new stimuli in the materials and the characterisation of these.

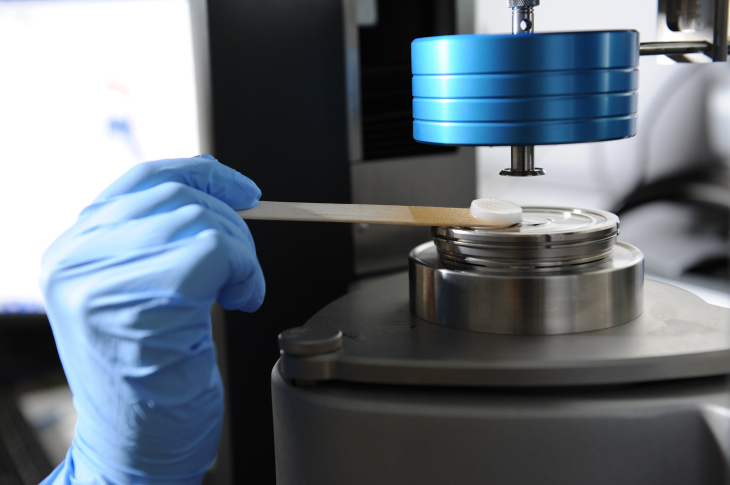

By investigating the optimisation of reactions as well as their upscaling, the department makes a significant contribution to the platform “qualified polymers and test bodies”.

Profile

Photo: Hereon

Development of polymer systems with tailor-made property profiles

The objective of the research is the design and synthesis of new materials, which are equipped with various respectively customised functions for the development and use of specific medical therapies.

When polymers are developed for applications in which organs or bodily functions are temporarily replaced or their tasks should be substituted, their controlled degradability is a key feature. Once the body has regenerated and its function is restored, the biomaterial is decomposed into its elements by endogenous enzymes and ultimately metabolised. By contrast, for the development of new stent materials, long term stability of the polymers may be desired. Meeting these demands can only be achieved in close co-operation with the other departments of the Institute and particularly the biocompatibility department.

By combining novel and established monomers, using both established and new synthesis processes, the most diverse polymers can be created, which can moreover also be linked to form polymer networks or other three-dimensional structures. Such links allow combination of the characteristic properties of the original substances. Polymer systems are created, whose processability, hydrolytic degradation ability and biocompatibility could be varied within a broad spectrum and which can be specifically adjusted by changing the molecular parameters.

Ring-opening, radical or cationic (photo)polymerisation are the most frequently applied syntheses techniques and the portfolio is rounded off with the use of polycondensation and polyaddition. The “Tianjin University – Helmholtz-Zentrum Hereon Joint Laboratory for Biomaterials and Regenerative Medicine” is a major partner here, providing monomer components in the required quantities.

Synthetic biomaterials

- Biodegradable polymers based on synthetic polyetherester, polyester or polydepsipeptide moieties

- Acrylic and polyether polymers for the production of biocompatible material systems that are not intended to degrade

- Thermoplastic elastomers, polymer network-, and hydrogel systems

Sound investigation of the polymerisation kinetics forms the basis for adjustment of the molecular parameters to achieve the intended property profile of the polymers. At the same time, the required foundations are laid for application-oriented, commercial upscaling of the syntheses, making it possible to supply several kilograms of material.

Photo: Hereon

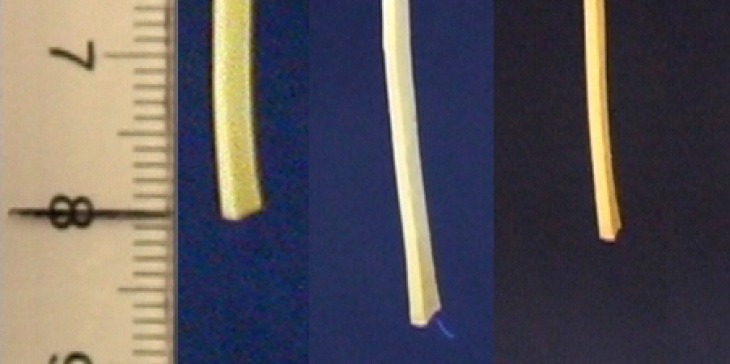

Shape-memory polymers are stimuli‐sensitive plastics, which are able to response to an external stimulus by changing shape.

If the deformation is caused by a temperature change then it is a thermally induced shape-memory effect. The shape-memory capability is a function that is based on the combination of an appropriate polymer architecture/morphology and a programming process (functionalisation) geared to this. Examples of applications in the biomedical area are minimally invasive surgery, remotely controlled switchable implants, and adaptive systems.

Thermoplastic elastomers and polymer network systems are developed by combining polycondensation and polyaddition. With the integration of specific molecular elements, these can be designed such that their external form can be switched by various stimuli. For doing so, the polymer compositions and synthesis processes are optimised such that polymers with the desired mechanical and thermal properties/ switching functions are created for the respective applications.

Whereas only one switching phase is available in classic two-form materials, the introduction of a second switching phase allows triple-shape-memory materials. Multiphase materials, in which one phase determines geometry and another phase can execute a reversible movement, enables reversible shape-memory polymers. Polymer systems with only one crystalline phase, which nonetheless has a very broad melt transition temperature, can be divided into a phase that determines geometry and a movement phase simply by means of thermomechanical treatment.

Magnetically induced shape-memory effect

Magnetically induced shape-memory effect of a polyetherurethane with embedded magnetic nanoparticles. Within 24 sec the temporarily fixed shape (rod) recovers into the original shape (spiral) inside of a magnetic field of an inductor ring.

Scientific milestones in Hereon shape-memory polymer research with far-reaching significance for the research area:

- Degradable, thermo-sensitive shape-memory polymers (SMP) (SCIENCE 2002, 296, 1673‐1676)

- Light‐induced SME in polymers (NATURE 2005, 434, 879‐882)

- Magnetically induced SME in nanocomposites (Proc. Natl. Acad. Sci. U.S.A. 2006, 103, 3540‐3545)

- Triple-shape polymers (Proc. Natl. Acad. Sci. U.S.A. 2006, 103, 18043‐18047)

- Multifunctional SMP systems (Adv. Mater. 2009, 21, 3394–3398)

- Temperature-memory polymers (Adv. Mater. 2011, 23, 4058‐4062)

- Magnetic‐memory effect in nanocomposites (Adv. Funct. Mater. 2012, 22, 184‐191)

- Bidirectional shape-memory polymers (Adv. Mater. 2013, 25, 4466-4469)

- Temperature-memory actuators (Proc. Natl. Acad. Sci. U.S.A. 2013, 110, 12555-12559)

Light-sensitive polymers

Lichtinduzierter Formgedächtniseffekt. Foto: Hereon

Plastics change their shape due to light: the range of applications of shape-memory polymers has been significantly expanded and numerous product innovations are expected as a result of the introduction of photosensitive material systems.

Press Release (in German)

Read more in "Nature"

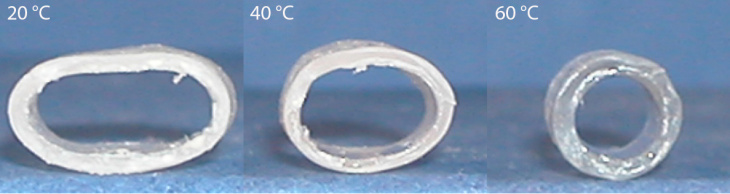

Triple-shape-memory effect

Foto: Hereon

“Triple-shape polymers” can change their form twice in succession with the aid of temperature and thus open up new opportunities for controlled applications in regenerative medicine.

Press Release (in German)

Read more in "PNAS"

Polymer actuators

Polymer actuators overcome the restriction of previously known shape-memory plastics (which were only able to switch once) by shifting back and forth between the shapes if the temperature is changed.

Press Release