New nanoparticle-reinforced magnesium materials

They reduce the ecological footprint of cars and aircrafts by lowering their weight: new magnesium materials, developed under the leadership of the Helmholtz Centre Hereon. In the OptUm-MagNa project - Optimised Formability of Magnesium Nanocomposites, magnesium composites are being developed that are interspersed with tiny ceramic particles. Funded by the Federal Ministry of Economics and Climate Protection with almost 900,000 euros.

The acceleration of a moving mass requires more energy the heavier it is. This old insight is the basis for the goal of the scientists at the Institute for Material and Process Design at the Helmholtz Centre Hereon to make vehicles and aircraft lighter.

This way they consume less fuel, which provide benefits for mobility customers and their wallets on the one hand, but also the environment. Because the CO2 footprint is significantly reduced.

It is estimated that a reduction of 100 kilograms in an average passenger car leads to a reduction in consumption of about 0.5 to 0.7 litres of fuel per 100 kilometres. The same is applicable to e-mobility. Electricity consumption is reduced, hence the range of e-vehicles is significantly increased due to their weight reduction. Additionally, the fact that smaller brake systems can be installed in a lighter vehicle, which in turn makes it even lighter.

The Future: Magnesium

Supported by the Federal Ministry for Economic Affairs and Climate Action

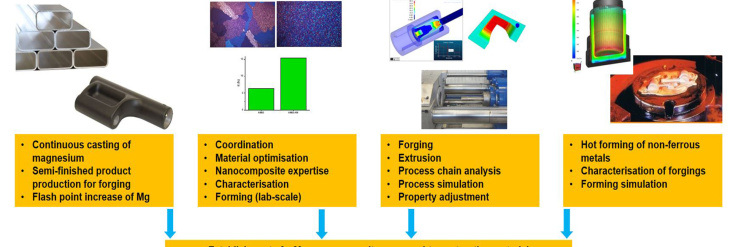

Researchers at the Helmholtz Centre Hereon have been working on magnesium materials for many years. In the current project, magnesium composites are now being developed that are interspersed with extremely small ceramic particles. "These particles improve the formability of the materials, which would significantly expand the area of application compared to conventional magnesium casting alloys. Because you can forge these materials or form them in other ways," says materials researcher and project leader Dr Hajo Dieringa.

This would allow magnesium materials to be used where today only steel or aluminium alloys are utilized, which are much heavier. This makes vehicles and even aircraft lighter and thus more sustainable.

The project also aims to promote the transfer of knowledge across industries and materials, addressing the automotive and aerospace industries as well as manufacturers of medical products.

The OptUm-MagNa project is funded with about 880,000 euros as part of the Technology Transfer Programme Lightweight Construction of the Federal Ministry of Economics and Climate Protection and is coordinated by the Helmholtz Centre Hereon. The Leuphana University of Lüneburg, Weisensee Warmpressteile GmbH and LMpv Leichtmetall Produktion & Verarbeitung GmbH are also involved in the joint project.

Further Information

Contact

Institute for Material- and Process Design

Helmholtz-Zentrum Hereon

Communication and Media

Helmholtz-Zentrum Hereon