EU-Project completed: With SELFMEM to intelligent membranes

The project “Self-assembled Polymer Membranes”, in short SELFMEM, which was funded by the European Union with the sum of 3.6 million euro, has now been completed with a final meeting held at the Helmholtz-Zentrum Geesthacht. The twelve partners of the SELFMEM group carried out research on self-organising isoporous membranes. The three year project was coordinated by the Institute of Polymer research.

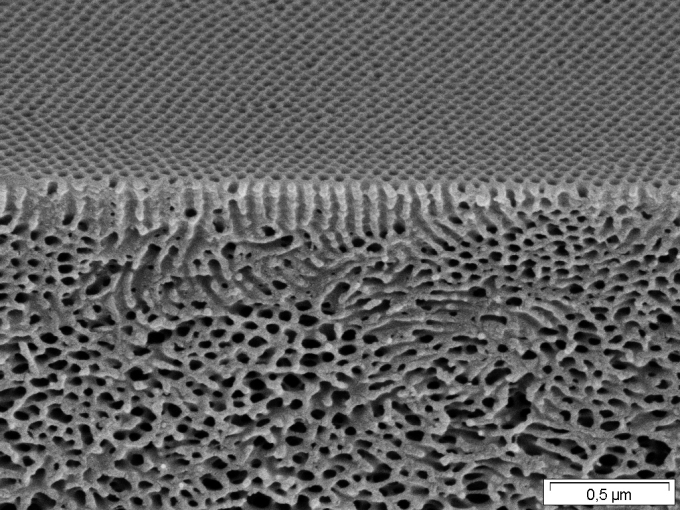

Self-organising isoporous block copolymer membranes, Photo: HZG/ Clarissa Abetz

Twelve project partners from science and industry within Israel, Canada and Europe are involved in the SELFMEM network. The research on self-organising isoporous block copolymer membranes was coordinated by the Geesthacht Institute director Prof. Dr. Volker Abetz.

Block copolymers consist of at least two monomer types which are linked to each other as polymer blocks in a single large macromolecule. As hydrophilic (water loving) und hydrophobic (water repellent) components are not compatible, they try to keep as much distance from each other as possible – they separate out into microphases. The macromolecules thus come to a certain structure of their own accord.

In the case of the extremely fine block copolymer membranes, the upper surface layer is highly ordered and uniformly permeated with pores. This serves as a filter and fulfils the separation tasks. The lower layer has a sponge-like structure and provides stability (see photo).

Developing self-organising membranes is a complex process. Prof. Dr. Volker Abetz explains, “At first we knew practically nothing about structure-property relationships and the parameters which are necessary for the formation of membranes.

At the final meeting in Swiss Neuchâtel: the SELFMEM-Participants

In 2011 membranes could be produced from chemically different block copolymers for the first time. In the process we established that solubility is a very important parameter. Very slight variations in the composition of the solvent can suffice to prevent a membrane from forming.”

It is assumed that self organisation commences in the solvent; the membrane structure is fully developed in the subsequent precipitation reaction. The temperature of the precipitation bath plays an important role hereby.

Even humidity and ambient temperature influence membrane production. The size of the pores depends, amongst other things, on the molecular weight and the composition of the block copolymers.

Depending on their pore size, self-organising membranes can filter different sized molecules, such as proteins, for instance, but also viruses and bacteria. In the course of the SELFMEM project we succeeded in producing membranes with minute pores of a diameter of 20 nanometres which could, for example, capture hormones and pharmaceutical substances in waste water. Catalytic processes could also be intensified with the aid of finer pores. Moreover, gas separation applications are also conceivable.

The Helmholtz-Zentrum Geesthacht has already applied for four patents, for instance, for “switchable” membranes. The pore size can hereby be adjusted later in the application via the temperature and the pH value.

“Their functionality can also be extended by means of a subsequent coating of the membrane” explains Prof. Dr. Volker Abetz. Polydopamine, for example, increases the hydrophilicity of the membrane and can thus have an inhibitory effect on membrane fouling. The HZG will present a report at the “Euromembrane 2012” congress at the end of September in London.

How the pores get into the membranes

It is not electrolytic etching which inserts the pores into the membranes, but an elegant trick. After their synthesis the block copolymers are first dissolved and then poured onto a fleece. In the course of a short resting phase some solvent then evaporates and cylinders are formed in the block copolymers which “grow” vertically downwards, commencing from the surface. The length of the resting phase is a decisive parameter for the formation of the upper, ordered separating layer and the lower disordered supporting layer. In the subsequent precipitation bath a solvent exchange occurs. The formed structures are hereby fixed.

Further Information

Centre for Membranes and Structured Materials

Contact

Helmholtz-Zentrum Geesthacht

Phone: +49 (0) 4152 87-1648

E-mail contactMax-Planck-Straße 1

21502 Geesthacht