First shape-memory plastics able to reverse deformation

Biomaterial researchers in Teltow have developed plastics that can repeatedly change from one shape to another and then back again when temperatures fluctuate within a selected range. The material, dubbed “polymer actuators” by its creators, thus overcomes a major limitation that affects similar materials. Up until now, polymers with temperature-controlled shape memory could only change form once.

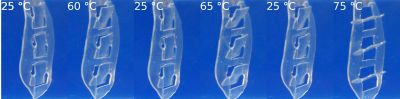

In this model of a window blind, temperature-memory polymer actuators are used to open and close the slats depending on how hot or cool it is. Users can program the temperature range in which the slats move. The term “temperature-memory” is used to describe this property. Picture: HZG/ Lendlein

The new material represents a breakthrough that will open up a wide variety of applications – from automatic blinds that function without electricity to new kinds of heat engines. Researchers from the Institute of Biomaterial Science in Teltow, part of the Helmholtz-Zentrum Geesthacht, have now presented the polymer actuators in the online edition of the renowned PNAS journal.

“Once the ambient temperature goes above and then below certain threshold values, our actuators can change shape many hundreds of times,” says Professor Andreas Lendlein, director of the Institute of Biomaterial Science. He explains that the programming of the plastics provides a relatively large amount of freedom for choosing the threshold values and the kind of shape change. He can therefore imagine a very diverse range of applications for the new material.

Tilman Sauter, a PhD student at the institute, gives an everyday example of where the plastics might end up: “The material could be used to make sun blinds that need no external electricity supply and are able to darken a room purely on the basis of how warm they are.”

This shows a model of a heat engine. A drive element (1) made of temperature-memory polymer opens out as it cools and in doing so moves a gear rack that then drives a wheel forwards. When it heats up, the drive element contracts and moves the gear rack back the other way. A second element (2) made of the reversible temperature-memory polymer forces the gear rack against the wheel when the rack is moving forwards and releases the wheel when it is moving back. Picture: HZG/ Lendlein

Another possibility is a heat engine, where the actuators would form the basis of a drive element. To demonstrate how the engine would work, researchers at the institute use an experiment that involves heating a plastic, which then opens up and moves a drive unit. When the temperature drops, the plastic returns to its original state. The temperature-memory effect makes it possible to control the rotational speed of the drive unit.

At a molecular level, the active polymers are built of structural elements that undergo changes to their mobility within a very wide temperature range. To transform the activity at the nano level to macroscopic movement, some of these structural elements are assigned to an internal scaffold that determines the geometry of the motion and orients the motion. “We can vary the proportion of motion elements to shape-giving elements, and this allows us to control the movement,” explains Dr. Marc Behl, head of the Active Polymers Department at the institute.

Publication

The Helmholtz-Zentrum Geesthacht is a member of the Helmholtz Association of German Research Centers and has sites in Geesthacht in the state of Schleswig-Holstein, and in Teltow in the state of Brandenburg (just outside Berlin). Its work, which is geared towards the long term and focuses on materials and coastal research, makes substantial contributions to solving major challenges facing society, science and the economy.