New concept for structural colors

Scientists of the University of Hamburg (TUHH), the ITMO-University in St. Petersburg and the Helmholtz-Center Geesthacht have developed a novel concept that enables colorants which are based on non-toxic materials, which further do not bleach in the sunlight and which do not lose their appearance under high processing temperatures (as needed for glazes of ceramics).

This is a press release by the Technische Universtität Hamburg (TUHH).

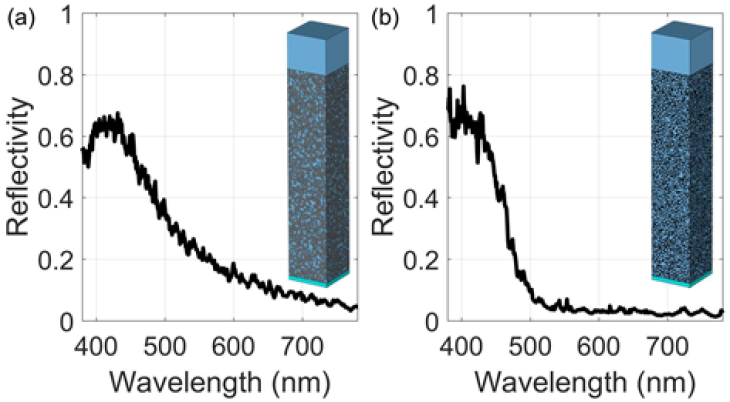

Comparison of the computed reflection spectrum of two photonic glasses. (a) consists of homogeneously filled spheres and (b) is build up from hollow sphere particles with a ceramic shell. The sphere diameter is around 200 nanometers and the thickness of the shell is around 10 nanometers.

The right figure shows a much steeper reflection spectrum which will produce a much higher saturation of the blue color.

Both blocks show cutouts of volumes filled with spheres which were the basis of the numerical simulations. Graphic: TUHH/ Guoliang Shang, Lukas Maiwald, Hagen Renner, Dirk Jalas,

Maksym Dosta, Stefan Heinrich, Alexander Petrov & Manfred Eich

In contrast to conventional pigments, the color effect is not caused by the absorption of certain wavelengths, which are in turn missing from the reflection spectrum and thus cause the color impression. Structural colors generate color solely by a structure that lets certain wavelengths destructively interfere.

Often such pigments feature a color impression that is dependent on the direction of illumination as well as the angle under which the pigment is looked at. This one wants to prevent in many cases. To realize “non-iridescent” colors, a certain amount of disorder in the structural arrangement of the colorant is needed. However, this disorder has lead, so far, to only weakly saturated colors.

The group of Hamburg based scientist have managed now to resolve these conflicting requirements. For this purpose a new concept was developed, which is based on weakly ordered arrangements of spheres – a so called photonic glass – combined with a precise design of the spheres themselves. The utilized hollow spheres have a diameter of around 200 nanometers with a ceramic shell of only around 10 nanometers thickness.

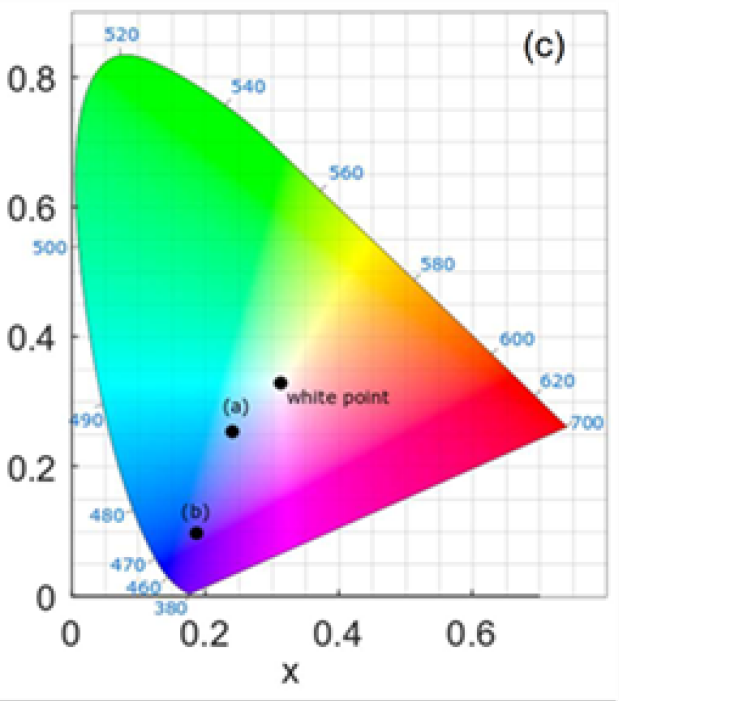

Chromaticity diagram: The positions of the two reflection spectra in (a) and (b) are shown in relation to the colorless white point. The diagram further shows the white point and the positions of the pure colors on the perimeter indicated by the corresponding wavelengths in nm.

The structure from hollow sphere particles produces a blue color much closer to the perimeter, thus a much purer color, than the structure from homogeneously filled spheres. Graphic: TUHH/ Guoliang Shang, Lukas Maiwald, Hagen Renner, Dirk Jalas,

Maksym Dosta, Stefan Heinrich, Alexander Petrov & Manfred Eich

Only the combination of the nearest neighbor ordering of these densely packed spheres and the hollow sphere character of the single particles allow a steep edge of the reflection spectrum (Figure 1b). The usefulness of this design approach is exemplified with a highly saturated blue color.

The photonic glass from hollow sphere particles produces a blue color much closer to the perimeter of the chromaticity diagram, thus a much purer color than that of the photonic glass from homogeneously filled spheres (Figure 1c). The team of researchers developed the theoretical framework for the description of this novel class of colorants and confirmed their predictions with extensive numerical simulations.

These principal findings which were produced under the lead of the scientists from Hamburg are further of importance for the development of non-toxic colorants, which also do not bleach under sun light and which are suited for high processing temperatures beyond 1000°C.

The manuscript was published in Scientific Reports, an Open Access-Journal of Nature.

Guoliang Shang, Lukas Maiwald, Hagen Renner, Dirk Jalas, Maksym Dosta, Stefan Heinrich, Alexander Petrov, and Manfred Eich, Photonic glass for high contrast structural color, Scientific Reports 8, 7804 (2018)

Contact

Institut für Werkstoffforschung, Helmholtz-Zentrum Geesthacht,

Phone: +49 40 42878 3147

E-mail contactTechnische Universität Hamburg-Harburg (TUHH), Institut für Optische und Elektronische Materialien,

Eißendorfer Straße 38, D-21073 Hamburg