Break-through in materials research

Hamburg scientists develop new materials class based on nanoparticles

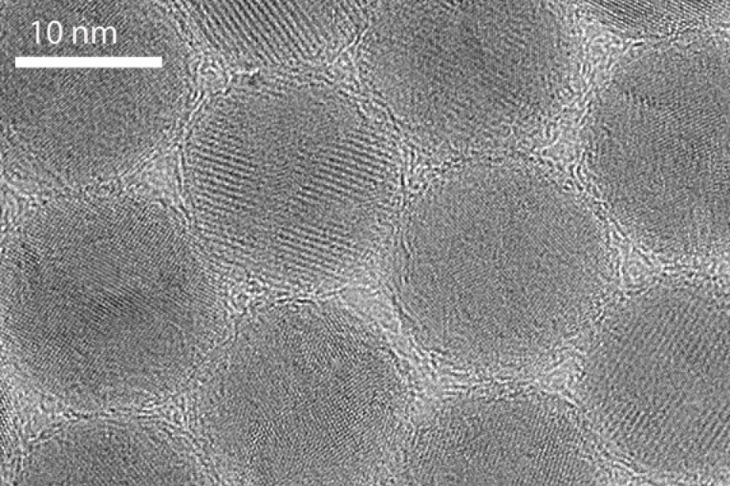

High-resolution transmission electron microscopic image of the iron oxide nanoparticles surrounded by oleic acid molecules. (Photo: TUHH)

Classic materials made of ceramics, metals or plastics possess their own typical mechanical characteristics. They are hard, soft, firm, ductile or rigid. Hamburg researchers have now developed a new material with the potential to combine all properties, opening up applications in the fields of medical technology and product manufacturing. A research team of scientists from the Technical University Hamburg (TUHH), the University of Hamburg, the Helmholtz-Zentrum Geesthacht and DESY were able to produce a new type of nanocomposite material. The work was published in the research journal Nature Materials, the most important academic materials science journal in the world.

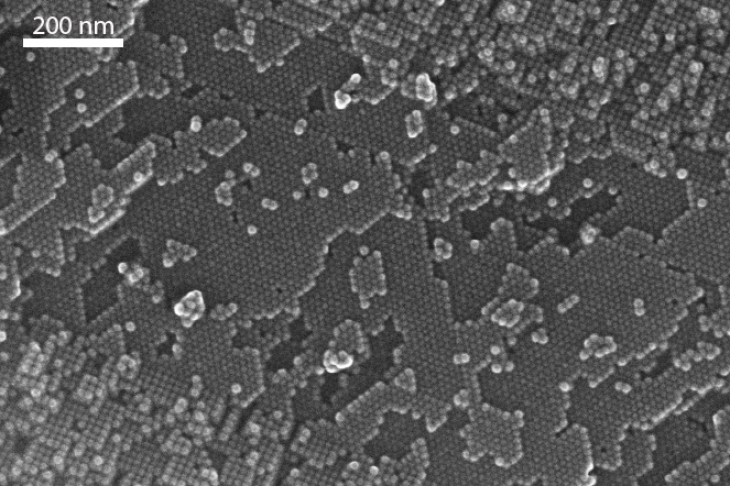

Scanning electron microscopic image of the regularly arranged iron oxide nanoparticles. The nanoparticle distance is so small that one cannot see the oleic acid. (Photo: TUHH)

The Hamburg researchers have brought the dream material for medical technology and product manufacturers a step closer. The newly developed methodology leads to a material with high elasticity and stability that at the same time possesses high hardness values. The researchers use a standard method utilised with nanoparticles, in which ceramic iron oxide nanoparticles are uniformly arranged at regular intervals. In order for this to occur, organic oleic acid is required, which positions itself in the narrow gaps between the nanoparticles and binds them together.

“The particle self-organisation leads to extensive densely packed superstructures, reminiscent of atomic crystal lattices,” says Dr Axel Dreyer, co-author of the study and scientist at the TUHH Institute for Advanced Ceramics. The highlight is that a subsequent moderate thermal treatment of the material results in much greater cohesion of the material, leading to new and yet unprecedented mechanical properties of the nanocomposite.

The structure of the new material on the smallest scales is similar to that of natural hard-tissue layers, such as mother of pearl or dental enamel. The components are uniformly-sized iron oxide nanoparticles encased in organic oleic acid. In past efforts, the bonds between the oleic acid molecules were very weak and based on what are known as van der Waals bonds. The authors have now managed to create a much stronger bond between the oleic acid molecules through drying, hot pressing and controlled thermal processing, which critically improves the nanocomposite’s mechanical behaviour. Because other nanoparticles are processed quite often in combination with organic oleic acids, this method could potentially lead to improvement in mechanical characteristics of many other nanocomposite materials. Furthermore, the organic molecules’ various alteration possibilities can influence the mechanical material behaviour, just as they do in nature.

The new material class was discovered in the Special Research Area 986 (SFB 986) “Tailored Multi-Scale Materials Systems - M³“ of the TUHH, in which the four research institutions cooperate. “Without the outstanding teamwork, we wouldn't have been able to develop this method," says Prof Gerold Schneider, SFB spokesperson and director of the Institute for Advanced Ceramics at the TUHH. The material can, for example, be used in dental fillings or in the production of watch casings. These applications require material that is both hard and resistant to breaking.

Publication in Nature Materials

DOI: 10.1038/NMAT4553. "Organically linked iron oxide nanoparticle supercrystals with exceptional isotropic mechanical properties“: Axel Dreyer, Artur Feld, Andreas Kornowski, Ezgi D. Yilmaz, Heshmat Noei, Andreas Meyer, Tobias Krekeler, Chengge Jiao,

Andreas Stierle, Volker Abetz, Horst Weller and Gerold A. Schneider; in Nature Materials.

Further information:

Technische Universität Hamburg-Harburg (TUHH)

Denickestrasse 15

D-21073 Hamburg