ESS/BEER

Within the framework of the Design Update Project for the European Spallation Source (ESS) funded by BMBF, novel neutron instrumentation concepts are developed by the HGF-centres FZJ, Hereon, HZB and by TUM. Hereon and partners from the Czech Republic successfully submitted a proposal for an engineering diffractometer (Beamline for European materials Engineering Research, BEER) at the ESS. Hereon is also involved in concepts for reflectometry, 3He-free neutron detectors, ESS-specific sample environment and the High Data Rate Initiative (HDRI) communication platform.

BEER

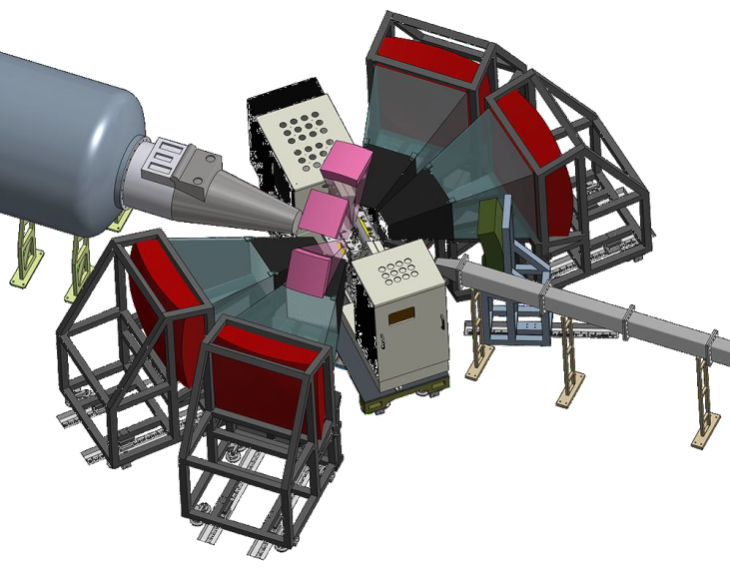

The BEER sample stage with the sample environment GLEEBLE and the detector banks (red) including the arc detectors (magenta) and the SANS scattering tube.

The Beamline for European materials Engineering Research (BEER) is a diffractometer dedicated to research with neutrons on engineering materials. The conceptual design has been developed together with Czech colleagues from Nuclear Physics Institute (NPI) in Rez. A joint proposal to build the instrument at ESS has been successfully submitted.

The challenge was to design an instrument taking advantage of the long pulse of the spallation source, leading to higher flux at the sample position than available at any other engineering instrument in the world. For this, the BEER design includes a novel chopper technique called pulse multiplexing. This technique allows extracting several short pulses out of the long ESS pulse leading to substantial intensity gain of up to an order of magnitude compared to pulse shaping methods.

Furthermore, BEER offers extremely broad intensity/resolution ranges and significant detector coverage, making it an ideal instrument for engineering science. Simultaneous SANS or imaging measurements without compromising diffraction investigations can be performed optionally.

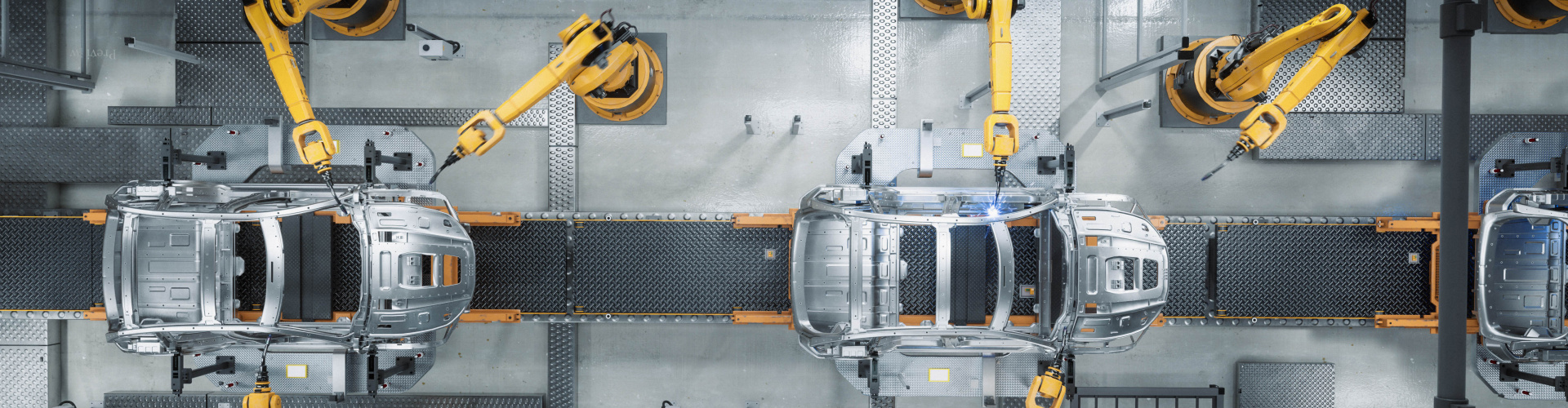

The outstanding performance of BEER together with standard and advanced sample environment, e.g. a GLEEBLE or a quenching and deformation dilatometer will push the frontiers of engineering materials research by neutron diffraction in the following fields:

• Residual stress analysis

• Texture analysis

• Phase analysis

• In situ and in operando investigations

• Studies of realistic industrial materials processing

Contact

Institute of Materials Research, Group "New Instrumentation for Neutron Scattering"

Phone: +49 (0)4152 87-1224

E-mail contactHelmholtz-Zentrum Hereon

Max-Planck-Str. 1

21502 Geesthacht

Germany

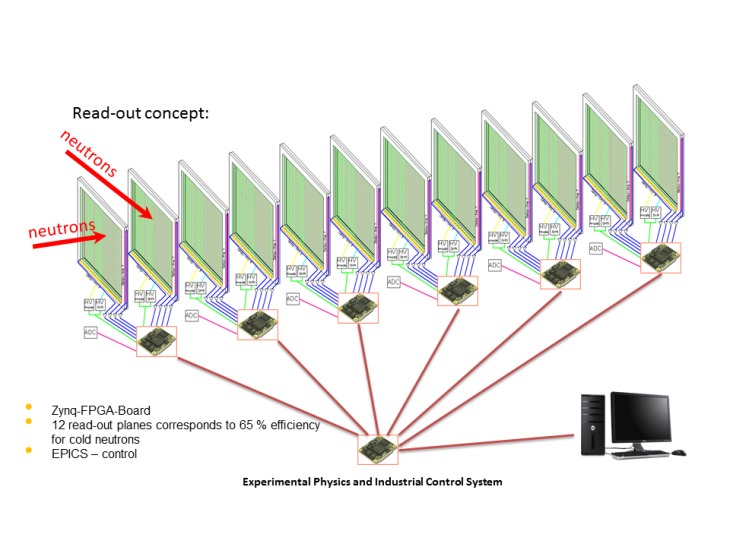

Detectors

The sample throughput of modern neutron scattering beam lines can only scale with the increase of primary intensity if the rate capability and efficiency performance of the detector system stay in pace with this development. For this reason and the reduced availability of 3He, which is conventionally used for neutron capture and so for detection, Hereon started 2011 in the framework of the in-kind program to the Design-update Phase of the European Spallation Source (ESS) in Lund to develop 3He-free neutron detectors based on Multi-Wire-Proportional-Chamber driven by 10B4C conversion coatings. In the beginning of this activity a coating recipe has been elaborated for the deposition of 10B4C, which allows for a uniform thickness, well adhesive and µm thick converter films onto Al thin plates [1]. Modern scattering techniques becomes more and more used in applied material science (neutron as well as synchrotron scattering techniques) and they develop more and more in direction of time resolved experiments with the aim to follow faster in-situ and in-operando processes, which require fast signal recording. Simultaneous application of several scattering techniques in one experiment likes SANS and diffraction etc. and the use of time-of-flight mode request large solid angle coverage by detectors for efficient operation. The resulting large 2D-detector coverage allows in this situation a broad band measurement of the momentum transfer from the neutron to the sample.

The constructive challenges in the manufacturing of such large 2D-area, 3He-free neutron detectors and the development of the supporting read-out and data processing electronics will be tackled by the engaged Hereon central technical department. The experience and knowhow yielded from the past and successful projects [2, 3, 4] allow for a focusing in this activity on search for engineering solutions in the fields of electronics, joining of heterogeneous materials and upscaling of known prototype detectors.

In a joint activity of the Hereon-TKA and Hereon-TKE it is planned to manufacture 1m2 2D-position sensitive detectors with a position resolution of 2 mm for the needs of the Hereon beam line “BEER” to get in operation a flag ship instrument of European material science at the European Spallation Source (ESS-Eric) in Lund [5].

Publications

[1] “Neutronenkonversionschicht”, M. Störmer, C. Horstmann, G. Nowak, R. Kampmann, J Hedde, Europäisches Patent Nr. 2 997 174 (15731384.2), Hereon-Az: 42806_0513EP/DE, (2016)

[2] ESS-TDR (2013), ISBN 978-91-980173-2-8

[3] G. Croci, G. Claps, R. Caniello, C. Cazzaniga, G. Grosso, F. Murtas, M. Tardocchi, M. Vassallo, G. Gorini, C. Horstmann, R. Kampmann, G. Nowak, M. Stoermer, “GEM-based thermal neutron beam monitors for spallation sources” Nucl. Instrum. Methods Phys. Res., Sect. A, 732, 217–220 (2013)

[4] G. Nowak, M. Störmer, H.-W. Becker, C. Horstmann, R. Kampmann, D. Höche, M. Haese-Seiller, J. - F. Moulin, M. Pomm, C. Randau, U. Lorenz, R. Hall-Wilton, M. Müller, A. Schreyer, “Boron carbide coatings for neutron detection probed by x-rays, ions, and neutrons to determine thin film quality” , J. Appl. Phys., 117, 034901 (2015)

[5] I. Stefanescu, M. Christensen, J. Fenske, R. Hall-Wilton, P. Henry, O. Kirstein, M. Müller, G. Nowak, D. Pooley, D. Raspino , N. Rhodes , J. Šaroun, J. Schefer, E. Schooneveld, J. Sykora, W. Schweika, “Neutron detectors for the ESS diffractomteres”, J. of Instrumentation, 12, P01019, (2017);

Contact

Institute of Materials Research, Group "New Instrumentation for Neutron Scattering"

Phone: +49 (0)4152 87 2560

E-mail contactHelmholtz-Zentrum Hereon

Max-Planck-Str. 1

21502 Geesthacht

Germany

Project Leader

Institute of Materials Research

Phone: +49 (0)4152 87-1268

Fax: +49 (0)4152 87-2666

E-mail contact