Core Topics

In the laboratories and technical rooms of the department of "Polymer Technology", tailor-made polymers are developed and synthesized as well as processed and characterized. The focus is on the synthesis of new materials for membrane applications for filtration and gas separation.

One further focus of the department is the production of polymers on a scale close to industry, paying special attention to the development of more environmentally friendly methods for polymer synthesis (e.g. emulsion or dispersion polymerization). Various controlled polymerization methods (e.g., RAFT, anionic polymerization) are used in combination with new reactor systems (e.g., Microfluidics) or large-volume batch reactors (up to 20 L). The synthesis can be controlled in situ by inline spectroscopy methods (1H, 13C, 19F NMR, IR, UV-VIS).

To realize a sustainable process, an important element in the upscaling of the polymer synthesis is the approach of largely recovering the contaminated solvents arisen during the polymer production by using membrane technologies developed at Hereon.

In addition, the department deals with the processing (compression molding, extrusion, foaming) of nanostructured materials as well as with investigations of their mechanical properties. In close interdepartmental cooperation, important findings are obtained for the optimization of new developments of all departments with the aim of developing new membranes.

- Emulsion & Dispersion Polymerization

- Microfluidics

- Batch Reactors

- Polymer Processing & Polymer Mechanics

- Modeling & In-Situ Characterization

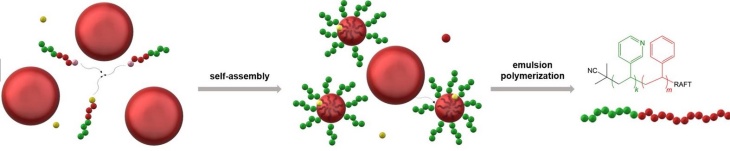

Radical polymerization in water - less organic solvents

Emulsion polymerization is a type of radical polymerization in which a polymer is synthesized in an emulsion of water, monomer, and surfactant. In the department of Polymer Technology, emulsion polymerization is even carried out without surfactant in order to synthesize polymers via controlled polymerization.

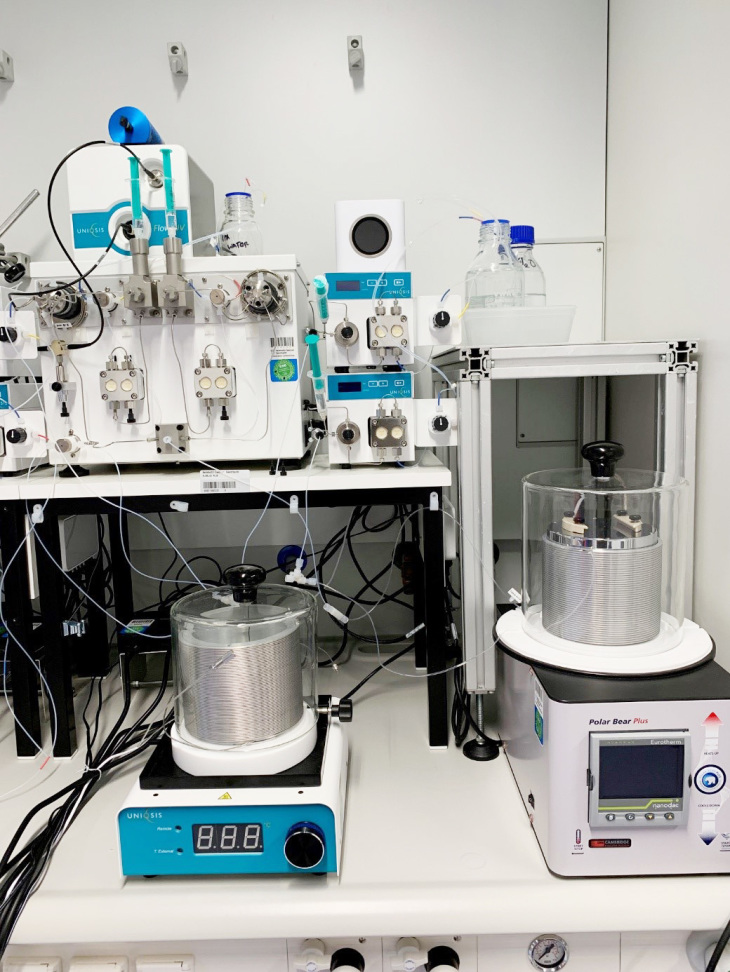

From micro to big

Photo: Hereon/Prokopios Georgopanos

The microfluidic reactors are types of reactors in which a given reaction (e.g., polymerization reaction) takes place on a micro scale. A high surface to volume ratio allows for rapid heat and mass transfer, permitting the chemical reaction to proceed in an efficient and safe way.

By controlling the flow, temperature, and pressure in-line, as well as the ability to intervene in the on-going reaction process, the synthesis can be optimized to automate operation and to scale up product synthesis through continuous operation.

Sufficient quantities for the technology transfer

Photo: Hereon/Prokopios Georgopanos

In order to produce polymers in sufficient quantities for the technology transfer, in addition to the microfluidic reactors also classic large batch reactors (up to 20l) are used. Polymer synthesis will be performed via controlled radical polymerization, via anionic polymerization as well as via polycondensation with the help of modern batch reactors. It is planned to start with the preparation of the monomers and solvents in specific reactors, followed by the polymerization in another reactor and finally the precipitation in specific precipitation reactors to collect the product in solid form for further applications.

In the near future, it is planned to recycle the contaminated solvents resulting from the polymer production using Hereon membrane technology so that they can be reused.

Application and testing of our polymers

Photo: Hereon/Schmid

The Polymer Technology department also deals with the processing of polymers for a variety of activities in the field of membrane research and also hydrogen storage. The processability of polymers is of great importance for the production of films and membranes, but also for the combination of different materials (production of composites or polymer blends) for further use in a variety of applications. The processing mostly happens in dry state, where possible without the use of solvents by means of extrusion, compression molding and also still foaming.

Important is also the in depth investigation of the mechanical properties of the polymers, composites that are prepared in different geometries such as the films or fibers. This is done by tensile tests or Charpy notched bar impact tests.

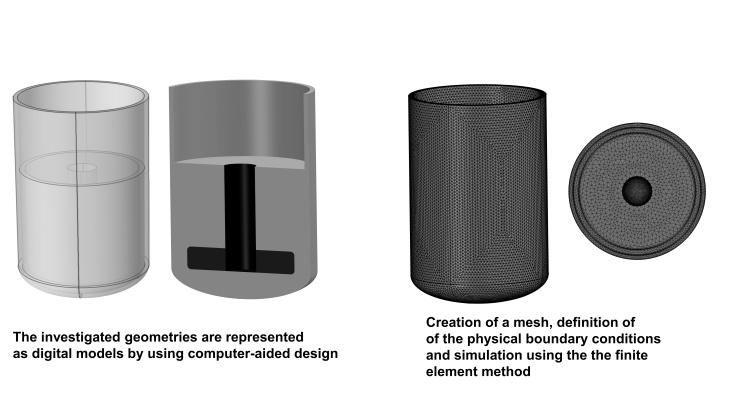

Optimization of the polymerization by simulation and modeling

Picture: Hereon/Felix Kandelhard

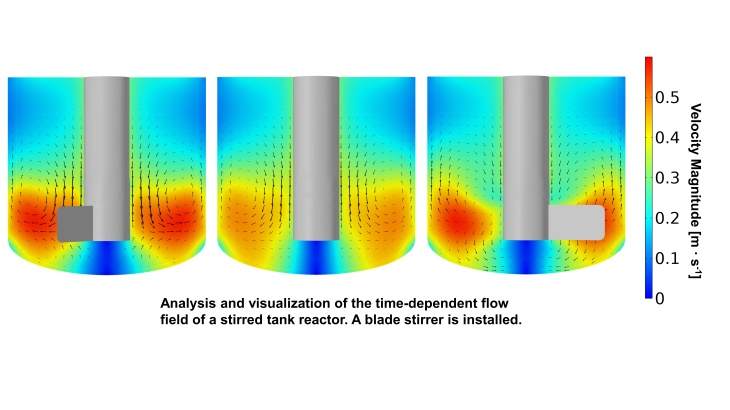

For the successful synthesis of the polymer in pilot scale, it is important to optimize the polymerization processes. For this purpose, the digitalization of the synthesis process in batch reactors as well as in continuous flow microfluidic reactors will be an important issue in the department of polymer technology. Models will be developed capable of describing and of performing the synthesis of the polymers in “digital form” with the help of a computer instead of consuming chemicals in the lab.

Picture: Hereon/Felix Kandelhard

A variety of scientific software is available for such an application such as COMSOL Multiphysics, OpenFOAM®, MATLAB, Aspen Plus® or Aspen Custom Modeler, etc.

For the validation of the models, it is essential to conduct the necessary experiments and to characterize the synthesized products thoroughly. This classical characterization is carried out in close collaboration with the other departments of the Institute of Membrane Research.

Additionally the synthesis process is monitored in-situ: via the implementation of NMR, FTIR and UV-VIS spectroscopy that are inline connected with the reactors, analysis of the samples is provided in real time. In this way, not only the necessary data for the model validation are provided, but it is also possible to intervene in the ongoing process to optimize synthesis and thus to avoid unwanted by-products.